![]()

![]()

![]()

![]()

PPS Service Center

![]()

Fort Lewis College

Extension 7000

![]()

Facilities Update

![]()

![]()

![]()

![]()

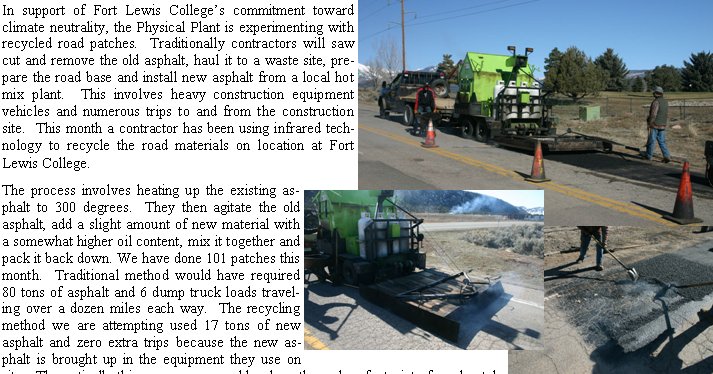

Recycled Road Patching

![]()

![]()

![]()

![]()

![]()

![]()

Trailers Prepare The Way For New Student Union Construction

The long awaited Student Union will have a groundbreaking dedication April 17th at 4:00 pm. Signs of the coming project can already be seen as FLC works to relocate programs that are currently in the CUB. Trailers are arriving and will be situated at the north west end of the Mears Apartments. The four trailers in all will be home to KDUR, the Environmental Center and the Independent News Paper until the entire Student Union project is complete in two years.

![]()

As mini projects and maintenance operations take place, waste materials from around campus have been brought back to the Physical Plant Services Yard and thrown in a trash roll-off. Once again we have been looking for ways to increase environmental responsibility. A new red recycling roll-off has been placed in the back lot. PPS employees will use this recycling container in place of the old green trash roll-off. Once filled, the container will be hauled off to Phoenix Recycling Center where it will be separated and inventoried. It is ONLY for Fort Lewis College official use—not personal items and we must make sure no traditional trash is put in this bin. It is possible we could save over 200 cubic yards per year of material which is presently put into landfills.